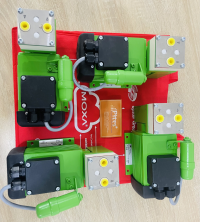

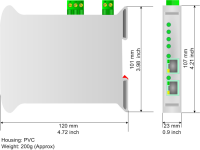

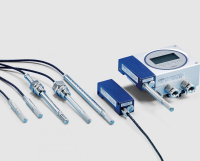

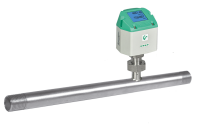

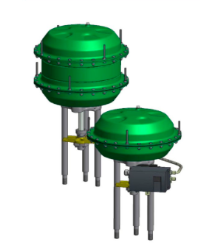

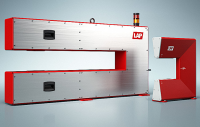

Beko technologies Vietnam, BEKOMAT®, BEKOMAT® Beko technologies Vietnam, đại lý Beko technologies Vietnam

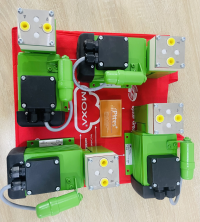

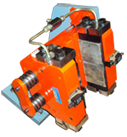

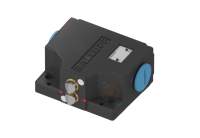

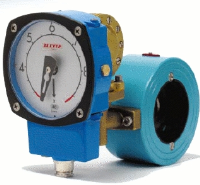

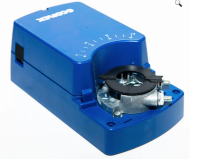

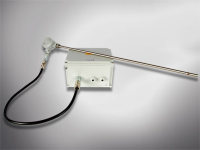

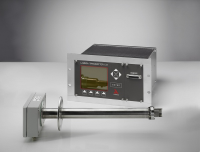

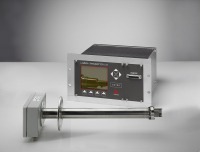

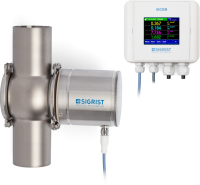

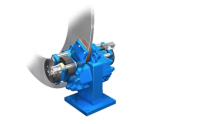

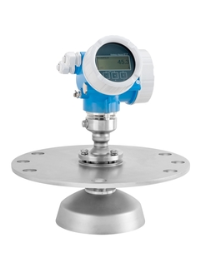

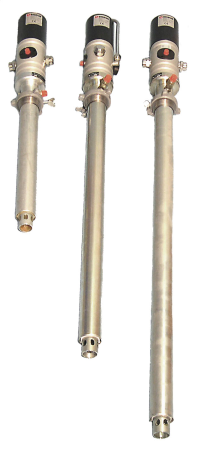

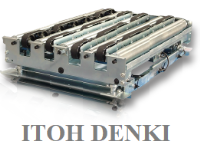

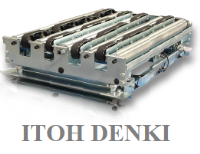

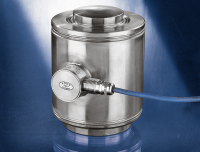

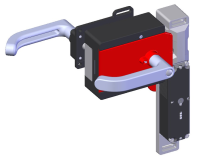

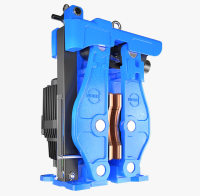

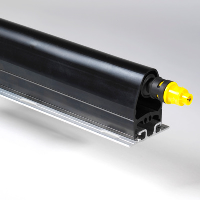

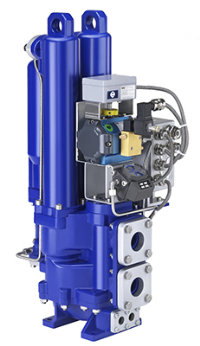

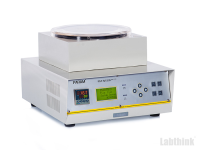

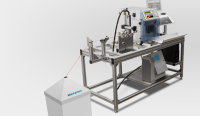

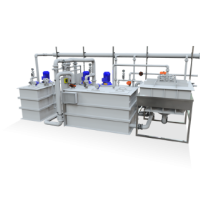

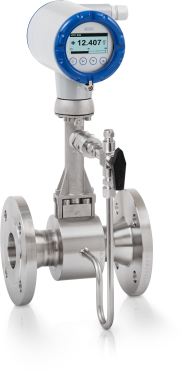

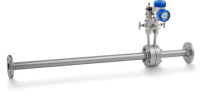

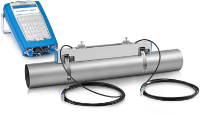

Condensate discharge with the BEKOMAT®

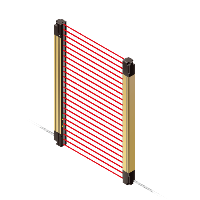

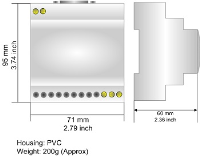

Condensation occurs at virtually every point along the compressed air treatment process. In most cases, it contains oil and dirt particles that should not enter the compressed air system. We help you remove condensate from your compressed air and achieve the optimum quality for your application: with the BEKOMAT. The electronic level controlled condensate drain has become synonymous with efficient condensate discharge. Volume-controlled and with intelligent electronics to prevent compressed air losses, it minimises energy expenditure and costs. This is not only our view but that of many renowned compressor manufacturers who recommend the BEKOMAT as they regard it as the safest and most economical condensate discharge unit currently available on the market.

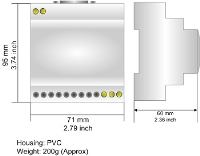

The condensate discharge requirements are ultimately determined by the purpose for which the treated compressed air is used. We aim at offering our customers optimised solutions for their specific applications. With our comprehensive range of condensate drains, we cater for virtually all compressor types and performance levels, system pressures and operating conditions – including of course highly specialised applications.

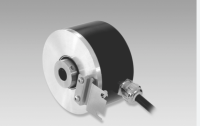

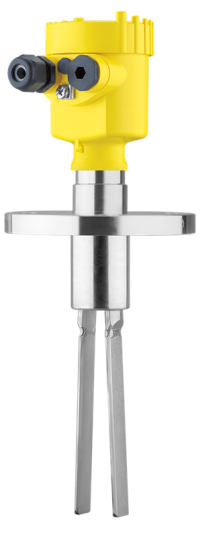

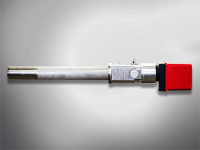

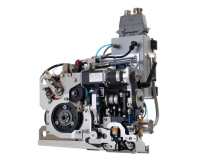

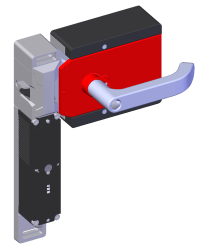

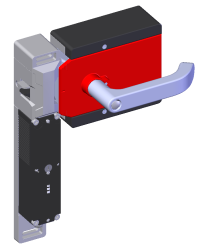

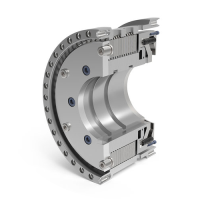

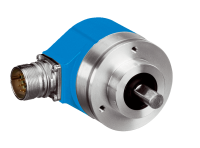

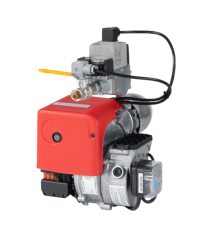

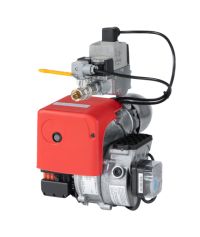

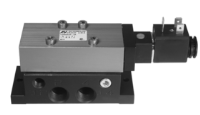

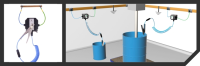

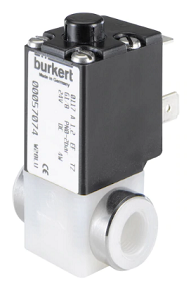

Function of BEKOMAT®

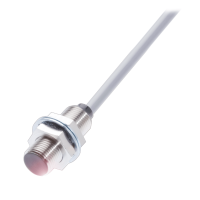

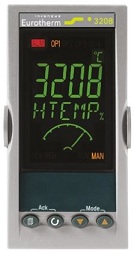

The BEKOMAT drains off condensate without loss of compressed air, thus reducing energy costs and CO2 emissions. This is made possible by the integrated capacitive sensor, smart electronics for volume-controlled condensate discharge and a proven pilotcontrolled solenoid valve with a special discharge diaphragm.