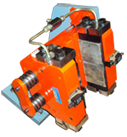

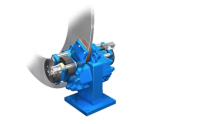

GATE VALVE

1. Pressure rating : ASME Class 150 to 4500

2. Size : 2-1/2" to 80"

3. Material

- Carbon steel

- Low alloy steel including ASTM A217-C12A

- Austenitic stainless steel

- Special alloy steel

4. Bonnet type

- Bolted type bonnet including lip seal type

- Pressure seal type bonnet

5. Disc type

- Flexible wedge disk

- Parallel slide disk (with spring)

- Parallel slide disk (without spring)

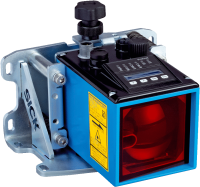

6. Option : Gear/Electric/Pneumatic operator, Bellow seal, By-pass line (w/valve), Equalizing line (w/valve), Extension stem, Limit switch, Locking device, Position indicator, Stem protector, etc.

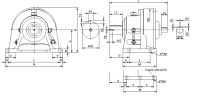

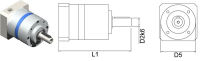

CAST STEEL GATE CLASS 600 & 900MATERIALS | DIMENSIONS

CAST STEEL GATE CLASS 600 & 900MATERIALS | DIMENSIONS

∎ Model No : GA6DA4 for Class 600, GA6XA4 for Class 900

∎ Pressure Seal Bonnet, Outside Screw & Yoke, Buttwelding

∎ Pressure-Temperature Ratings : ASME B16.34

CAST STEEL GATE CLASS 1500 & 2500MATERIALS | DIMENSIONS

CAST STEEL GATE CLASS 1500 & 2500MATERIALS | DIMENSIONS

∎ Model No : GL4FA4 for Class 1500, GL4GA4 for Class 2500

∎ Pressure Seal Bonnet, Outside Screw & Yoke, Buttwelding

∎ Pressure-Temperature Ratings : ASME B16.34

GATE VALVE

1. Pressure rating : ASME Class 150 to 4500

2. Size : 1/2" to 6"

3. Material

- Carbon steel

- Low alloy steel including ASTM A182-F91

- Austenitic stainless steel

- Special alloy steel

4. Bonnet type

- Bolted type bonnet

- Pressure seal type bonnet

- Seal welded type bonnet

5. Disc type

- Solid disk

- Flexible wedge disk

- Parallel slide disk (with spring)

- Parallel slide disk (without spring)

6. Option : Electric/Pneumatic operator, Bellow seal, Extension stem, Limit switch, Locking device, Position indicator, Stem protector, etc.

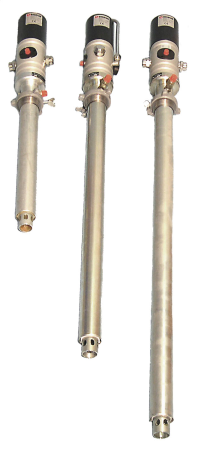

Special Valve

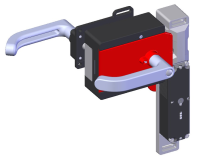

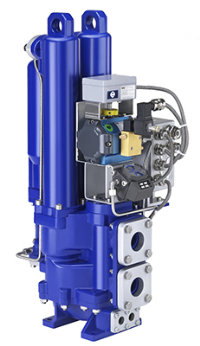

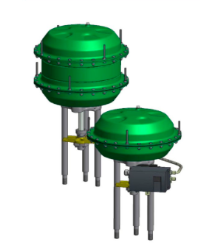

BLEEDER TRIP VALVE (NON RETURN STOP CHECK VALVE)Details

BLEEDER TRIP VALVE (NON RETURN STOP CHECK VALVE)Details

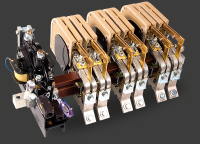

Bleeder Trip Valves always have operated same as general swing check valves.

But it makes to high seating thrust with the assistance of the pneumatic cylinder actuator when it is needed

more tightly seating. Also, Bleeder Trip Valves are straightthrough valves usually operated automatically.

These valves are equipped with a safety pneumatic actuator that provides assistance to the valve at the beginning of closing operation. But it has high height because it must have high lift length and the stop

lift check valve has disadvantages for horizontal pipelines.

The type of Bleeder Trip Valve's actuator is single acting. When the solenoid was only energized, the air pressure of the actuator's cylinder is emission, and then pre-loaded spring of the actuator is extended, that is, seating mode. This type is simple and free from air fail and electrical fail. When electrical fail occur, although the

seating mode is unable remotely, it is more important to be continued in operation mode than the seating mode.

The solenoid valve of Bleeder Trip Valve's actuator is the normal open type and so when you directly supply air, the actuator' stem is up and the crank arm rotate in counterclockwise. This state is on operating mode and Bleeder Trip Valve operate same as general swing check valves. If the fail occur in air line, because Bleeder

Trip Valve's actuator has connected the air check valve in air inlet pipe the actuator is on lock state.

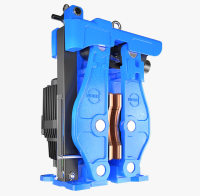

Electro-Magnetic Relief ValvesDetails

Electro-Magnetic Relief ValvesDetails

1. Electro-Magnetic Relief Valve, called as the power control valve is used as final safety device to prevent over-pressure of the high pressure boiler for the power plant High level requirements are made on it's operation, seal ability, stability, and durability.

2. The valve body has sufficient rigidity and exhaust port is provided at both sides.

3. Valve Poping action by electro-Magnetic operation

4. As for the disc material, Inconel 750 which has high strength against high temperature, excellent in erosion-proof, and having sufficient experience is employed for both the main valve and pilot valve discs.

5. Stellite No.6 is employed for the seat.

Feed water Heater Level Control ValveDetails

Feed water Heater Level Control ValveDetails

1. Precision water level control of boiler feedwater heater.

2. Maintain sufficient water level in steam generating unit.

3. Available precision level control by a special structure of disc and cage.

4. Use alloy steel parts considering both high temperature and high pressure.

5. Anti-cavitation trim.

6. Pneumatic Diaphragm actuator.

Super Heater & Reheater Spray Injection Control ValveDetails

Super Heater & Reheater Spray Injection Control ValveDetails

1. Inject boiler feedwater pump flow to main steam flow.

2. Available precision flow control by a special structure of disc and cage.

3. Body : Cage guided globe & angle type valve.

4. Anti-cavitation trim.

5. Pneumatic cylinder actuator.

Boiler Feed Water Pump Minimum Flow Control ValvesDetails

Boiler Feed Water Pump Minimum Flow Control ValvesDetails

1. Installed in recirculation system to prevent BFWP from overheat

2. Apply for high differential pressure service

3. Minimize the erosion phenomenon caused by cavitation under the high differential pressure

4. Anti-cavitation trim by multi-stage variable orifice

Turbine Ventilator ValveDetails

Turbine Ventilator ValveDetails

1. During turbine bypass operation, the valve is opened to allow cooling steam to flow thru the turbine. In this mode of operation desuperheated steam from bypass flows back through the HP section of the turbine to prevent overheating.

2. When the turbine trips, or as a result of load rejection, the steam in the turbine HP section becomes bottled up and, due to windage losses, may overheat that section. To prevent overheating cold reheat steam flows back through the HP turbine.

3. Advantages in maintenance, hard packing structure, no need gland packing.

4. Reinforced sealing system between body and bonnet by hot bolting connection.

5. Operated by hydraulic actuator.

Turbine Blowdown ValveDetails

Turbine Blowdown ValveDetails

1. The Blowdown valve function is to vent the turbine shaft packing between the high pressure and reheat turbine sections to condenser as a result of turbine trip or loads loss, and then to prevent the turbine to overspeed caused by the steam in the HP turbine section to flow along the turbine shaft into the reheat section through the shaft packing.

2. The valve can be opened quickly in small thrust because of pilot type seat.

3. Advantages in maintenance, hard packing structure, no need gland packing.

4. Reinforced sealing system between body and bonnet by hot bolting connection.

5. Operated by pneumatic actuator.

Safety ValvesDetails | OVR

Safety ValvesDetails | OVR

1. Maintain stability of system and equipment when exceeding the set pressure

2. Applied thermal disc structure considering thermal stress

3. Precision set pressure is available by adjust screw

4. Lift length or blowdown capacity is controlled by upper ring

5. Leakages, blowdown and chattering are controlled by lower ring

6. Hunting phenomenon is controlled by adjusting collar

7. Available manual operation

Continuous Blowdown ValveDetails

Continuous Blowdown ValveDetails

1. Blowdown the precipitation continuously from boiler drum to maintain high purity of the feedwater

2. High susceptibility of erosion by high differential pressure and saturated steam

3. Available precision flow control

High Durability Drain ValveDetails

High Durability Drain ValveDetails

1. Drain Valve is one of a high durability valve installed in main steam or superheat outlet drain line for thermal power plant

2. Prevent disc and seating surface damage from scale oxide ejection occurring often in piping or erosion caused by steam blowing at high differential pressure, DSS or WSS operation in high temperature & high pressure

3. Quickly separate changeable seat

4. Angle type durable for erosion

5. Stem & Disc integral, to prevent failure by vibration from throttling service

6. Slit for relaxation of thermal stress is applied to prevent crack may be caused by thermal expansion on seating surface

7. Throttling type for flow control

8. Decreased the cavitation phenomenon by reducing the pressure recovery by widening outlet opening area of the seat

9. Valve seat surface have both seal area and throttle area. Seal area is wider than throttle area to maintain sealing when throttle area damage due to scale oxide ejection

10. Delta Seal Ring is applied to maintain sealing by thermal transient at the time of starting plant

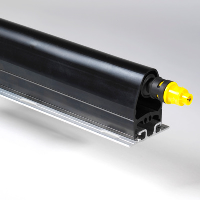

Butterfly ValveDetails

Butterfly ValveDetails

1. Is light, and without special support, can install in Pipe line

2. Flow control is good

3. Sealing is achieve by elastically deforming the seat

4. Seat design offers the advantage of being easily replaceable in the field

5. Mechanically retained on the disc ; adjustable with access from flanged end of the valve

Diaphragm ValveDetails | OVR

Diaphragm ValveDetails | OVR

- Gland Packing does not need

- In vacuum or poisonous fluid widely used

1. Rubber Diaphragm

- Lining is easy (Is suitable in corrosive fluid)

- Low pressure drop

2. Metal Diaphragm

Y-Non Return ValveDetails

Y-Non Return ValveDetails

1. Streamlined flow passages and the absence of turbulence-producing cavities behind the disk allow stable fluid movement through straight-flow body

2. Pressure drop is 70% less than other streamlined globe valves. (Equivalent length L/D : 40~50)

3. Guide separated from body provide continuous guiding of valve disk from the open to closed position. This guide offers the good seat alignment and stable operation

4. Y-NRV yield lower pressure drop than other pattern, because they permit a more nearly straight through flow path

∎ Model No : GA6AA1 for Class 150, GA6BA1 for Class 300

∎ Bolted Bonnet, Outside Screw & Yoke, Buttwelding

∎ Pressure-Temperature Ratings : ASME B16.34