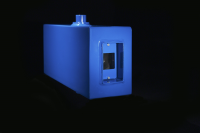

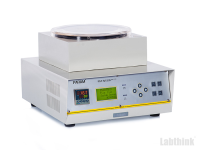

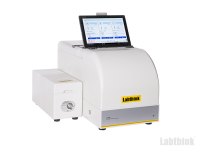

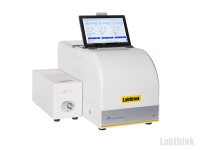

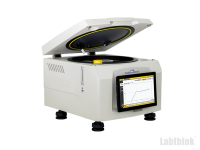

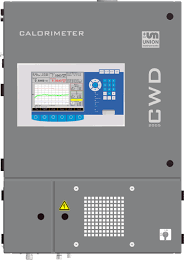

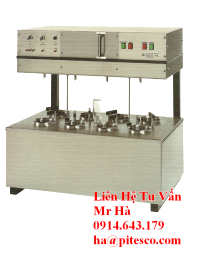

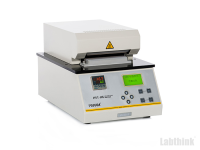

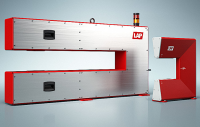

Labthink Vietnam, C390M Labthink, Hệ thống kiểm tra tốc độ truyền hơi nước C390M, Đại lý chính hãng Labthink Vietnam

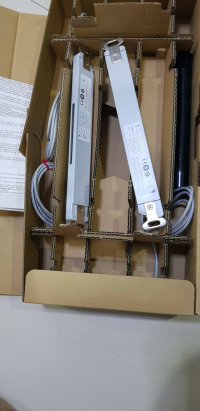

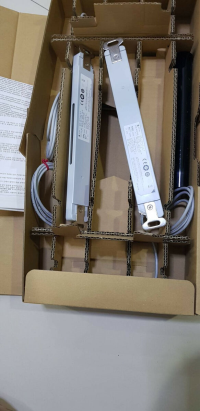

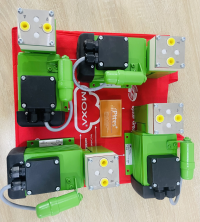

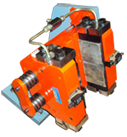

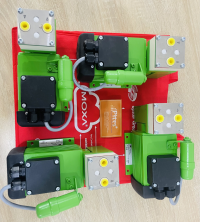

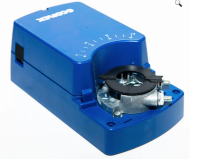

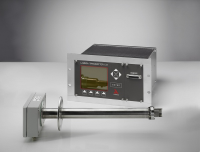

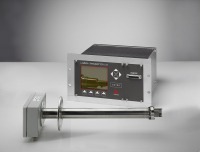

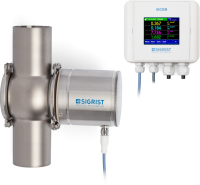

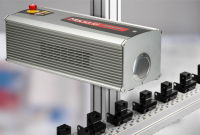

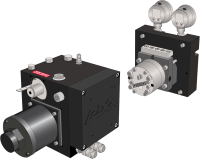

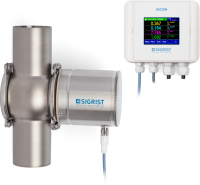

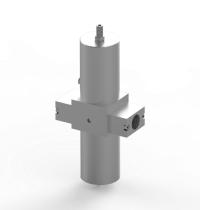

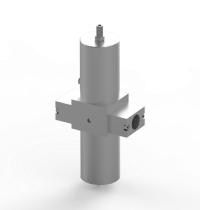

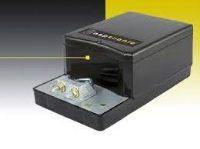

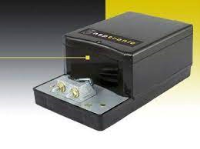

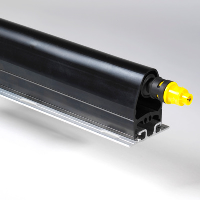

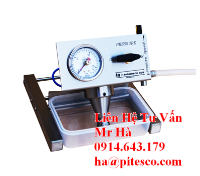

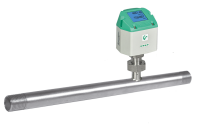

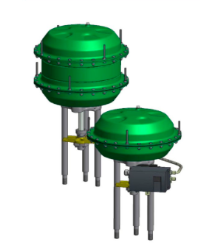

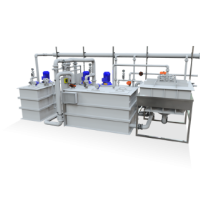

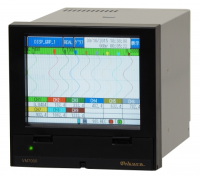

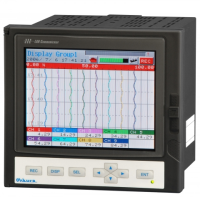

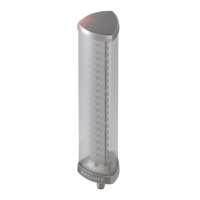

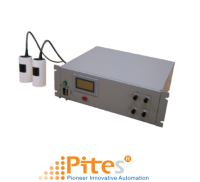

C390M Water Vapor Transmission Rate Test System, is designed and manufactured based on infrared sensor method and conforms to the requirements of ISO 15106-2/ASTM F1249. This instrument can be used to measure the water vapor transmission rate of barrier materials with high, medium and lower moisture barrier properties with a wide testing range and high testing efficiency. The instrument is featured with patented design of integrated block consisting of 3 test cells. Equipped with high precision sensors and professional computer-controlled system, the instrument can regulate and control the temperature, humidity and flow rate properly, which guarantee the testing sensitivity and repeatability of test results. C390M is applicable to determination of water vapor permeability of plastic films, sheeting, paper, packages and other relative packaging materials in food, pharmaceutical, medical apparatus, daily chemical, photovoltaic and electronic industries, etc.

Product Features

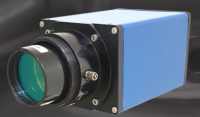

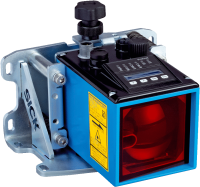

Innovative Sensor Technology

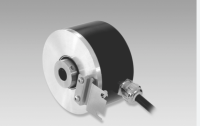

The instrument uses Labthink’s new generation water vapor analytical sensor, which is developed by Labthink Global Research & Development Center, collecting top class scientific and technical achievements in Chinese and American sensor technology fields. With core sensor technology, the precision and stability reach world advanced level.

Best Products Created by Mature Process

With 30 years’ experience, Labthink has most mature and reliable manufacturing technology of gas permeability testing instruments. Labthink provides customers with high-end barrier property testing instruments with best design, best material, best performance and best sensor by continuously adjusting the details, completing the designs and improving the performance.

Complete Product Line for Various Standards

By studying various test methods of water vapor transmission rate, Labthink manufactures many water vapor permeability testing instruments based on ASTM E96/GB 1037 (gravimetric method), ISO 15106-2/ASTM F1249 (infrared sensor method), ISO15106-3 (electrolytic sensor method) and ISO15106-1/ASTME398 (humidity sensor method). Labthink has the most complete product line of water vapor permeability testing instruments in packaging industry worldwide.

All for Customers

Labthink is dedicated to providing customers with suitable products. From scientific tracing method to commercially applied method, from scientific research to quality control, you will finally find the products that are suitable for you. C390M Water Vapor Transmission Rate Test System is one of those products.

- Precise adjustment of temperature, humidity and flow rate of test gasNote3

- Short warm-up time. Test conditions can be achieved in a very short period

- Liquid cooling agent, catalyst or special mixture of gases are not needed

- Professional test mode and fast test mode can meet requirements for different applications or materials

- Reference films are available for system calibration use

- Core sensors and other key parts have self-protection features

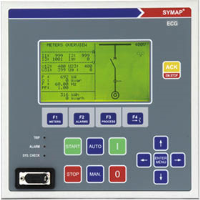

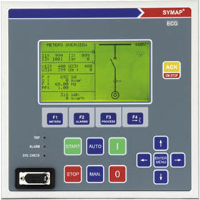

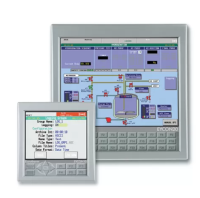

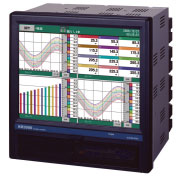

- The instrument is equipped with internal computer, requiring no external computer

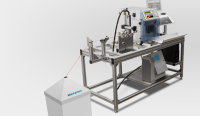

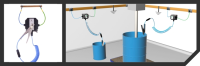

- Package testing is supported

- Intelligent gas saving feature can help reduce the consumption of test gas

- Net connection and USB ports are available

- Professional software is easy to use. Multiple levels are defined for users. Various forms of reports.

- Labthink exclusive DataShieldTM Note2 provides the users with safe and reliable management of test data and test reports.

- Computer system required by China GMP is available for medical industry.

- CFR21 PART11

Test Principle

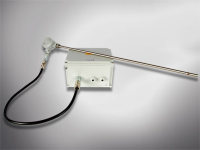

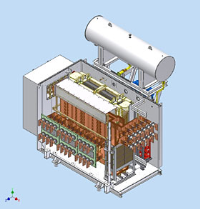

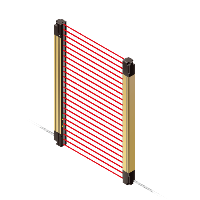

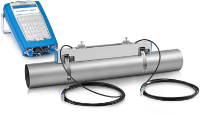

The test specimen is mounted in the diffusion cell, which is subsequently divided into a dry chamber and a controlled-humidity chamber. The dry side of the specimen is swept by a flow of dry nitrogen, and the water vapor permeating through the specimen from the controlled-humidity chamber is carried by dry nitrogen to the infrared sensor where proportion electrical signals will be generated. The water vapor transmission rate is obtained by analyzing and calculating the electrical signals. For package specimen, the dry nitrogen flow inside the specimen while the outside of specimen is in high humidity environment.

Test Standards

This test instrument conforms to the following standards:

ISO 15106-2, ASTM F1249, GB/T 26253-2010, TAPPI T557, JIS K7129, YBB 00092003-2015

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

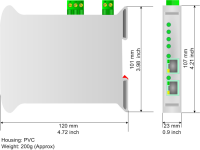

Technical Specifications

Table 1: Test Parameters Note1

| Parameter \ Model | C390M | |

|---|---|---|

| Test Range | g/(m2·d) (Standard) | 0.05 ~ 40 |

| g/(pkg·d)(Package) | 0.00025 ~ 0.2 | |

| Resolution | g/(m2·d) | 0.001 |

| Repeatability | g/(m2·d) | Bigger one of ±0.05 and 2% |

| Test Temperature | °C | 10 ~ 55 ±0.2 |

| Test Humidity | RH | 5% ~ 90% ±1%, 100% |

| Additional Functions | Package Test (3L Max.) | Optional |

| DataShieldTM Note2 | Optional | |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional | |

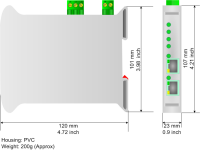

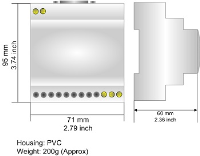

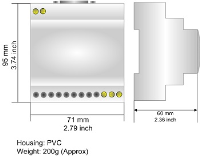

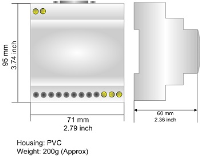

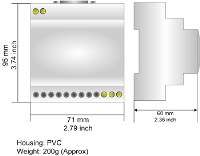

Table 2: Technical Specifications

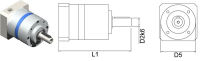

| Test Chamber | 3 test chambers |

|---|---|

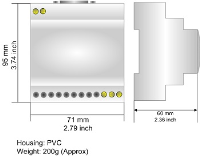

| Specimen Size | 108mm X 108mm |

| Specimen Thickness | ≤3mm |

| Standard Test Area | 50cm2 |

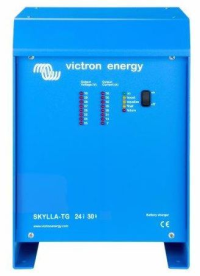

| Carrier Gas | 99.999% High-purity Nitrogen (outside of supply scope) |

| Carrier Gas Pressure | ≥0.28MPa / 40.6psi |

| Port Size | 1/8 inch metal tubing |